Olivewood Chil-LED™ is the only lighting system that is exclusively designed for use in refrigerated environments. Chil-LED™ is unique in that the compact, lightweight LED light source is the only part of the system that is actually inside the cold area. All of the other components – the electronic control systems, heat sink, mounting brackets – are situated outside the cold room, in the ambient environment. Chil-LED™ is the leading energy saving cold store lighting product on the market.

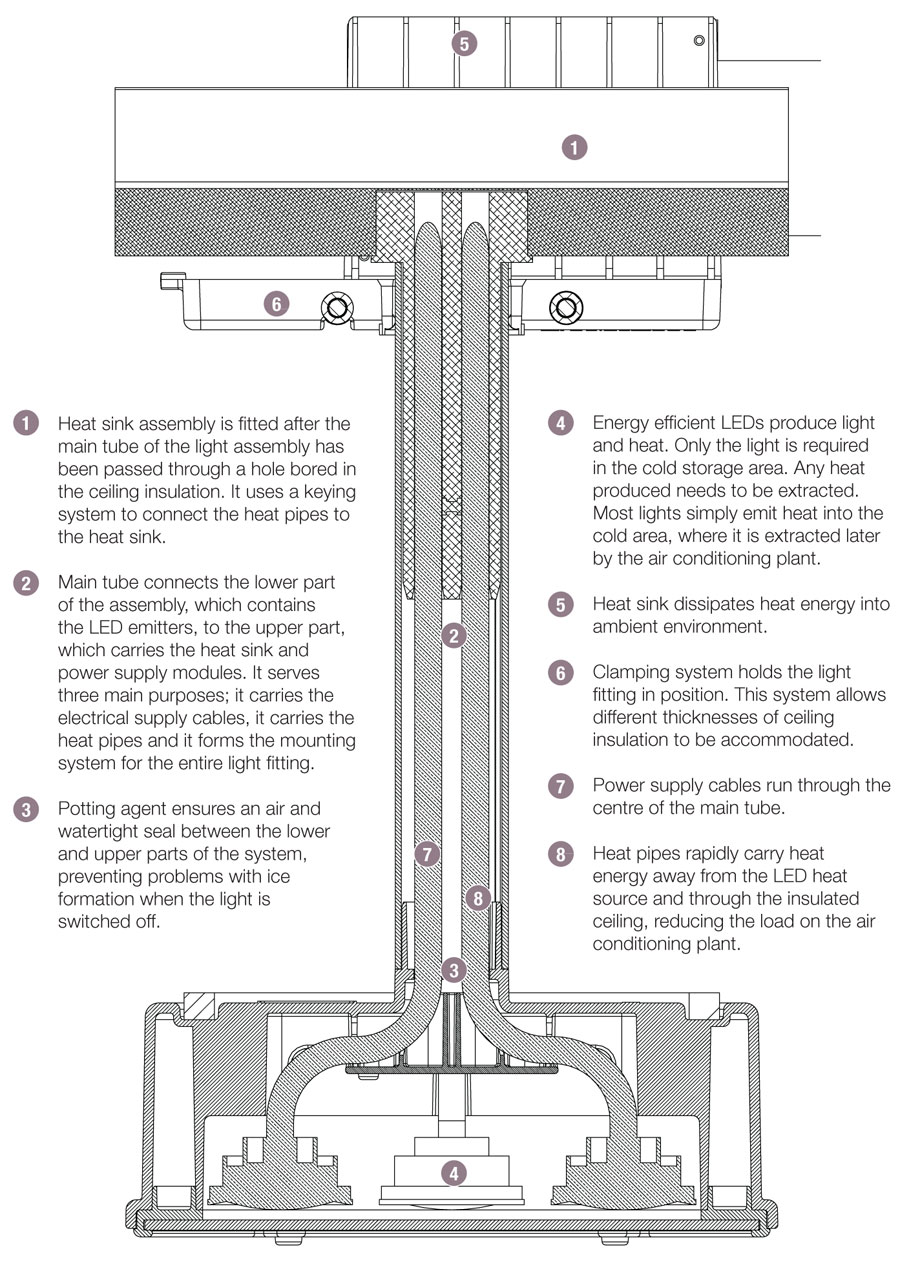

Chil-LED™ overcomes the traditional conflict between good lighting and efficient refrigeration in cold rooms. Lights are sources of heat and, in cold rooms, heat gain from lighting is a costly problem. Maintaining a refrigerated environment is an energy-intensive operation. The air conditioning equipment uses power as it works to remove heat. LEDs (Light Emitting Diodes) are exceptionally efficient light sources. However 70% of the energy that they consume is lost as waste heat. In ordinary lights, this unwanted heat by-product is radiated into the cold room. Olivewood Chil-LED™ uses an advanced heat transit system, known as a heat pipe, to extract the heat from the light at source. It is then redirected and transported through the insulated envelope ceiling, and dissipated outside the cold store.

Chil-LED™ is far superior in it’s design and application. Olivewood has made Chil-LED™ the first choice when it comes to replacing increasingly obsolete lighting systems within cold places.

Cold room designers insist on maintaining the integrity of the insulated walls and ceiling panels of the cold room. Every hole through a panel needs to be completely sealed to prevent warm, moist air from entering the temperature controlled area, creating problems with condensation and icing. Most lights have multiple mounting points and a separate cable entry point - all of which require holes in the insulation to be drilled, filled and sealed. The unique Olivewood Chil-LED™ design combines the mounting bracket, cable entry and heat extraction system in one unit, which requires only a single mounting hole. This design reduces installation costs and ensures the integrity of the insulated panel.

Chil-LED™ is an ultra-low profile design, reducing ceiling clutter, maximising usable space and avoiding the possibility of impact from fork lift trucks. In cases where ceiling clearance is very tight, Chil-LED™ can even be recessed into the insulated panel, creating a flush, level surface. Olivewood Chil-LED™ is a unique, bespoke and innovative lighting system that offers a wide spectrum of features and benefits. It is unrivalled in its efficiency, performance, practicality, quality and reliability. Chil-LED™ provides maximum immediate and long term financial savings with excellent returns on investment.

| Product Version | Chil-LED 56 | Chil-LED 80 |

|---|---|---|

| LED Power | 56 Watts | 80 Watts |

| System Power | 63 Watts | 87 Watts |

| Voltage Range | 220-240Vac rms nominal | 220-240Vac rms nominal |

| Power Factor | 95 | 95 |

| Drive Current | 350mA | 500mA |

| LED Efficacy | 120Lm/W | 115Lm/W |

| LED Initial Output | 6720Lm | 9200Lm |

| Maintained Lumens | 6600Lm | 8400Lm |

| CCT | 5000 | 5000 |

| CRI | 80 | 80 |

| Beam Angle | 26⁰ / 50⁰ / 80⁰26⁰ / 50⁰ / 80⁰ | 26⁰ / 50⁰ / 80⁰26⁰ / 50⁰ / 80⁰ |

| Weight | TBA | 3.15KG |

| Driver Type | Harvard Engineering CLQ2700S-240-C | Harvard Engineering CLQ21000S-240-C |

| Driver Qty | 1 | 2 |

| Driver Efficiency | 89% | 89% |

| Heat Pipe Capacity | 60 Watts | 60 Watts |

| Mounting Cutout Dia | 34mm | 34mm |

| Max Insulation Thickness | 200mm | 200mm |

| Min Insulation Thickness | 50mm | 50mm |

Unit S1, Mendip Industrial Estate

Mendip Road

Rooks Bridge

Somerset

BS26 2UG

T: +44 (0)1749 840 439

E: info@olivewoodtech.co.uk

W: olivewoodtech.co.uk